"P.A.C. di Bezzetto Sandro & C. S.N.C. ", thanks to its forty years of experience on the market for the production of printed circuit boards can boast about the implementation of some ideas that made history in the R&D of printed circuit boards.

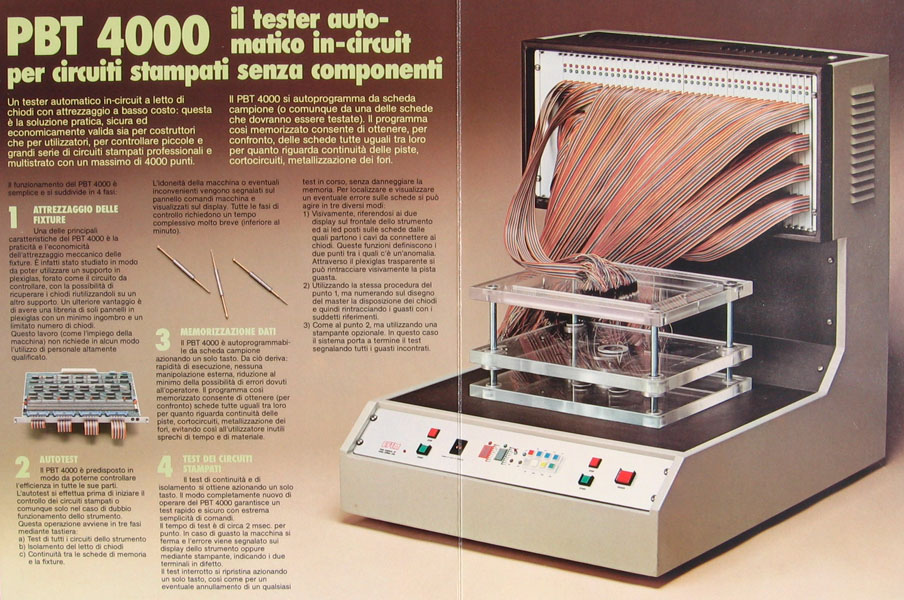

1970 - Design of the "PBT 4000", the first machine in the world capable to perform electrical continuity tests and track insulation tests, naturally operating thanks to a self-taught approach because the "GERBER" computer language had not yet been invented. The machine was used in P.A.C. laboratories for almost 10 years, that is, until the building of the current standard machines for electrical test.

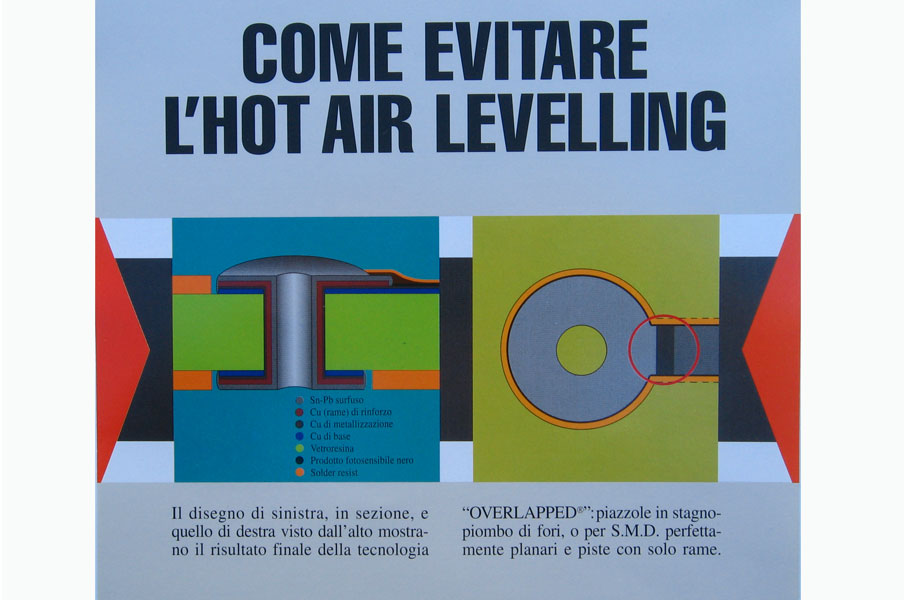

1995 - Patent of the OVERLAPPED PROCESS that allowed obtaining pads and tracks tinned with Tin/Lead 60/40 alloy perfectly flat without using Hot Air Solder Leveling (H.A.S.L.) finish. This process remained in use until the appearance on the market of "chemical tin", which was launched in 2002; this process prevented the use of five machines respect to those used by our competitors, with related saving of labor, plants, disposal of exhausted liquids and washing water to be treated at the purification plant.

1996 - P.A.C. was the first company in Italy to use conductive polymer to metalize the holes of professionally-made printed circuit boards. The process consists of depositing a conductive plastic material called "3,4-ethylenedioxythiophene" on the wall of the hole to be metalized. Derived from pyrrole and synthesized by a German multinational corporation, the basic molecule was developed by P.A.C. and then adopted by many other Italian companies.

1996 - With the aim of simultaneously printing the solder resist on both sides of the printed circuit board, the ROLL TWINS, a horizontal rotary printing machine, capable of reaching a printing speed of 10-12 m/min on panels with about 650-700 mm wide, was designed and built. Currently, the fourth version of the machine is in use, improved and revised, and it allowed P.A.C. to remove from the printing department six flatbed machines.

2002 - Introduction of Selective Chemical Tin. In order to comply with the Directives 2002/95/EC ("RoHS" regulations) and 2002/96/ EC ("WEEE" regulations), P.A.C. established a cooperation with ORMECON® a German company, owner of a theoretical chemical process that was both simple and high quality. A production line was designed and after a year of experiments in cooperation with ORMECON®, which in the meantime obtained the NOBEL® Prize 2001 for the electrically conductive chemical compound named "polyaniline", used in the process, excellent results were obtained on Tin deposit, ensuring weldability, flatness and a high storing period.

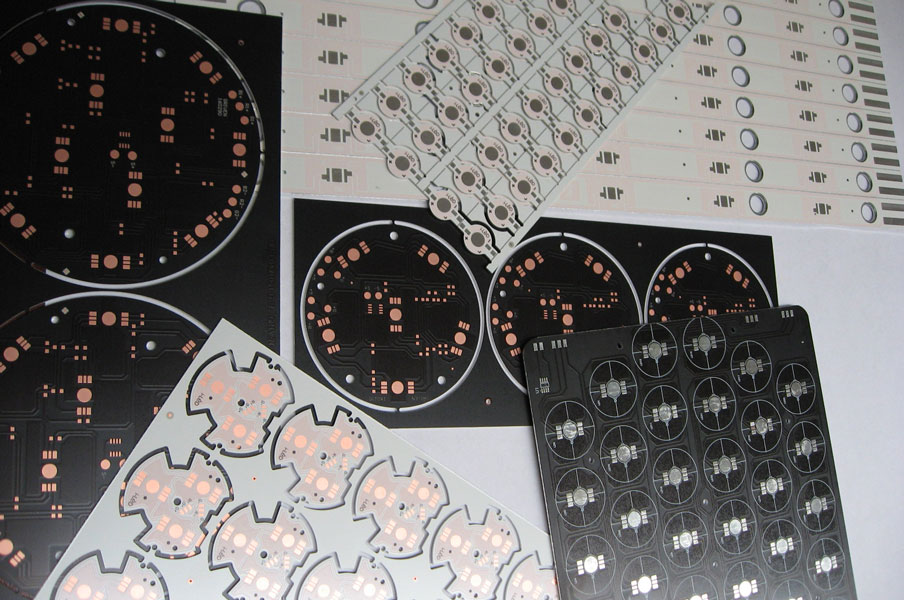

2005 - P.A.C. , at the Microelectronics exhibition in Vicenza presented the first printed circuit boards with aluminum substrate to be used in the lighting sector. Visitors were very impressed and interested in the new technology which at that time was little known. Thanks to a collaboration with one of its long term customer in that sector, the company drew the attention of visitors from the RGB (Red - Green - Blue) LED lighting products, which were the major news of the whole event.

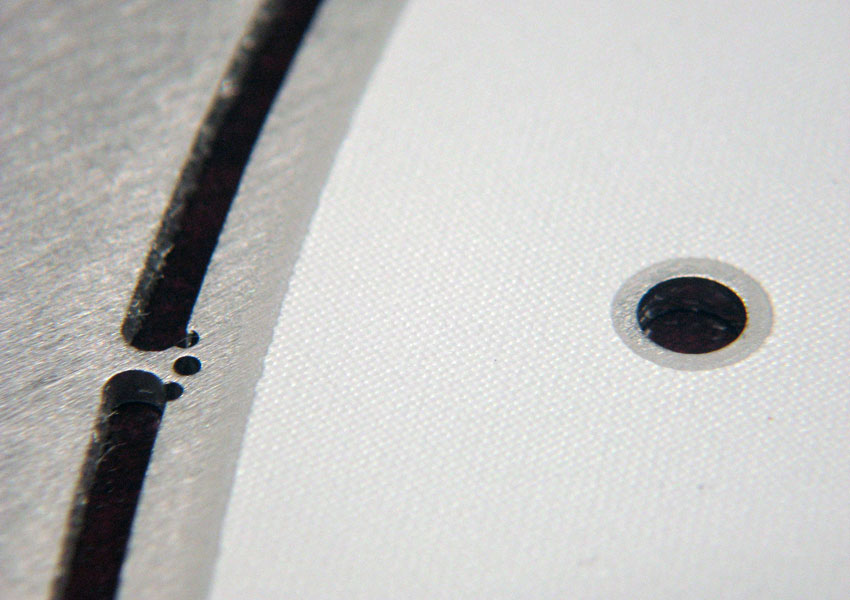

2008 - Thanks to its R&D department, P.A.C. introduced in its manufacturing cycle insulated hole technology making use of a particular dielectric resin which allowed the optimization of the various projects on PCB with Metal Core (metal substrate); it was also possible to manufacture insulated holes for the passage of power cables, through the PCB Metal Core, reducing the space occupied by the wires except in their welding points. This allows an easy positioning of all lighting devices and in particular the insertion of the LED modules in tight housing spots.

2012 - P.A.C. introduced a new mechanical processing for MCPCB: threading of the board mounting holes. The standard threading available are from M2 to M4, custom threading on request are evaluated on a case by case basis.

2013 - Since its MCPCB products comply with the UL standard, P.A.C. is authorized to apply the "UL" and cULus marks on the Metal Core material, thus providing an additional quality service to customers accessing an international market.

2015 - P.C.A. started the new year by introducing the use of the "PTS" ( Silk-screened thermal paste) in its silk-screening department; the new advanced technical solution, made in Germany by the PETERS company, is a printable paste for silk-screen, which is electrically insulated and resistant to welding cycles. It is applied between the printed circuit board and the heatsink or components that dissipate heat; its elasticity ensures a reliable thermal connection, improving the transfer of heat dissipated, so as to efficiently lower the temperature during the operation of power electronic devices, such as MOSFET, IGBT, Triac and even PowerLED. The "PTS" is an alternative solution to the use of the SMT metal heat sinks due to their excessive costs or assembly problems. P.A.C. in October participated in the "ILLUMINOTRONICA" (Lighting & electronics), a national exhibition of PadovaFiere, and presented its entire range of products requiring special machining dedicated to the needs of the sector.